SERVICES

About KWICKSILVER

Kwicksilver is a full-service alloy wheel repair network. Our technicians straighten bent rims and repair all cosmetic damage to aluminum rims, including curb rash, scrapes, gouges and discoloration caused by age.

All Kwicksilver technicians utilize state-of-the-art wheel repair equipment and methods that we have developed.

Rim Straightening

Kwicksilver technicians can straighten virtually any bent car or truck rim. Whether it’s a 15″ OEM or 24″ custom rim – no wheel repair job is too small or too large. We repair steel, chrome, and aluminum rims.

Kwicksilver uses state-of-the-art straightening devices to achieve the most accurate repair possible. Each rim is first inspected with a highly sensitive dial indicator, which carefully measures the wheel to determine the exact location and severity of the bend. The bent alloy wheel is then repaired and brought back to original manufacturers’ specifications via our specialized techniques and machinery.

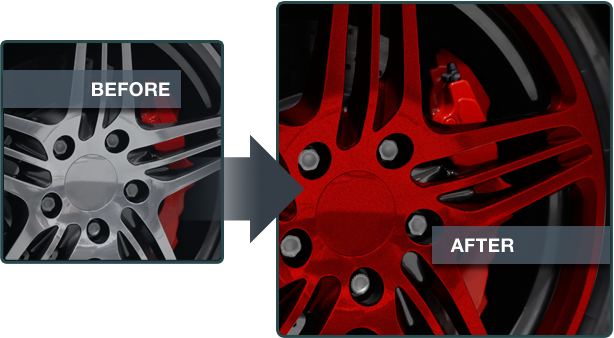

Cosmetic Repair & Polishing

With our reconditioning tools, proprietary paints and clearcoat process, we can remove curb rash, scrapes, gouges and discoloration caused by age. It’s a specialized process that ensures a match with the undamaged wheels. Polished aluminum wheels can also be brought back to like-new condition with our vibratory drum polishing machine.

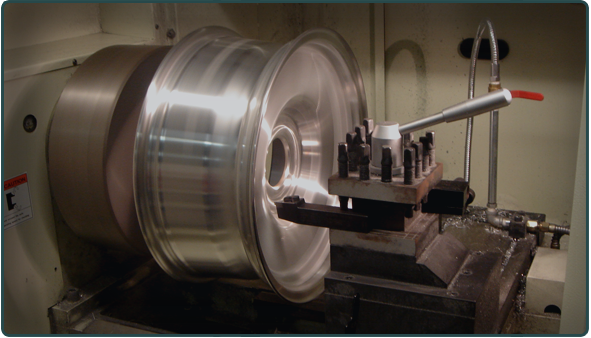

CNC Machining

Many of our fixed shops are set up to offer CNC machining on a state-of-the-art CNC wheel lathe. This device is completely computerized and cuts a fine layer of aluminum from the entire face of the rim with exacting precision, producing a perfect finish equal to or better than original factory finishes.

Original equipment manufacturers are increasingly putting machined rims on their new vehicles. A machined faced wheel has a bright finish much like polished aluminum. However, upon closer inspection, machined rims have tiny circular machine lines cut into the aluminum. The only way to properly repair a machined wheel is with a CNC lathe. Some wheel repair providers offer a cheap coverup technique when it comes to machined wheels. That is never done at Kwicksilver.

Welding

It’s not uncommon for a pothole or curb to create a small stress crack in a wheel. When this happens the wheel is likely to be bent as well. Metal fatigue can also play a part. Some of our customers notice a certain roughness in the handling of the car. But many times it’s simply a chronic loss of air in the tire that is the tell-tale sign. If you’re losing a considerable amount of air in the same tire every few weeks, its a good bet that your rim is bent and possibly cracked.

Kwicksilver technicians are trained to handle this type of wheel welding repair and use only top quality TIG (Tungsten Inert Gas) welders. Some cracks are unsafe to weld, such as those located on the spoke of a rim. In this case, your Kwicksilver technician will find a replacement OEM rim at a fraction of the cost of a new rim.

PVD Chroming

Kwicksilver uses a new chroming method based on physical vapor deposition (PVD). This is the new standard in this kind of finish. Traditional chroming methods are outdated and hazardous. Our PVD chroming service is 100% environmentally friendly, using no hazardous materials and producing no hazardous waste.

Better still, PVD has a 5 year warranty (typical chrome is 1 year) and its sealing properties prevent oxidation of the wheel that would otherwise result in peeling and pitting, especially under winter conditions. PVD coatings are also 80% lighter than traditional chrome.

Kwicksilver is offering PVD chroming in traditional bright finish (ice) and a darker finish (black ice). Turnaround time is approximately 5 days to strip and 5 days to coat.

Powder Coating

Kwicksilver now offers powder coating at most locations. It is the new alternative to automotive liquid paints. Most new cars now have powder coated rims. The powder comes in a wide range of colors and finishes and is extremely durable and long-lasting.

The powder material is applied with an electrostatic gun. The gun imparts a positive electric charge on the powder, which is then sprayed towards the grounded object (wheel) by compressed air and then accelerated toward the object by a powerful electrostatic charge. The process creates an incredibly smooth finish that will last for many years.

Wheel Protection Package

Kwicksilver is now offering Wheel Protection Packages that cover all cosmetic scrapes, dings and gouges. Choose from 3, 4, or 5 year programs. All four wheels are covered and these programs allow for unlimited repairs.

Keep your wheels looking new for the life of the car. Avoid expensive wheel repair costs when you return your leased vehicle back to the dealer.

All aluminum and machined wheels can be covered. Chrome rims are specifically excluded. Your vehicle can be new or used as long as the wheels are in like-new condition upon signing. Contact us today for pricing on your vehicle.